Additive Manufacturing (3D Printing) Advisory Bureau and Training Services

With the 4th Industrial Revolution (“Industry 4.0”) upon us, the technologies that have transformed other segments of the economy — the Internet of Things, big data and artificial intelligence, to name a few — are reshaping the industrial space, driving improvements in productivity and automation. But, as drastic as these changes have been, one thing has more or less remained the same: the manufacturing process itself.

That may be changing with the dawn of “Industry 4.5,” as priorities shift to sustainability, speed-to-market, and supply chain resiliency. Additive Manufacturing (AM), synonymous with 3D printing, creates objects layer by layer and has the potential to transform manufacturing as we know it, expanding design freedom, reducing time to market, bringing production closer to demand and improving industrial sustainability.

Research analysts outline three key points for understanding how Additive Manufacturing could transform segments of the $14 trillion global manufacturing industry.

- Traditional manufacturing impedes innovation, sustainability and supply chain resiliency

- US engineers across industries ranked AM as a top technology priority for investment post-COVID

Comparing Additive and Traditional Manufacturing

- AM represents a paradigm shift in design, manufacturing and distribution

Applications of Additive Manufacturing (3D Printing) in various Industries.

- Aerospace

- Automotive

- High Tech Equipment

- Energy, Oil and Gas

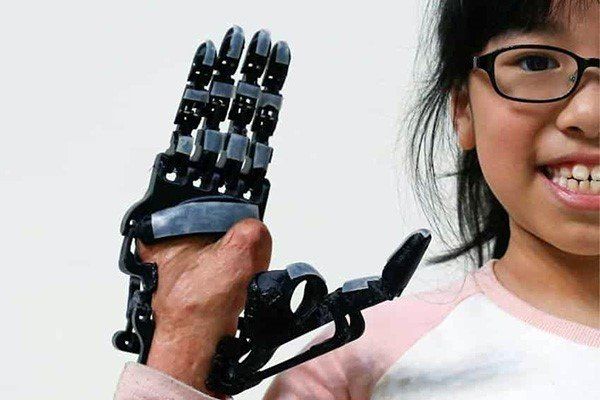

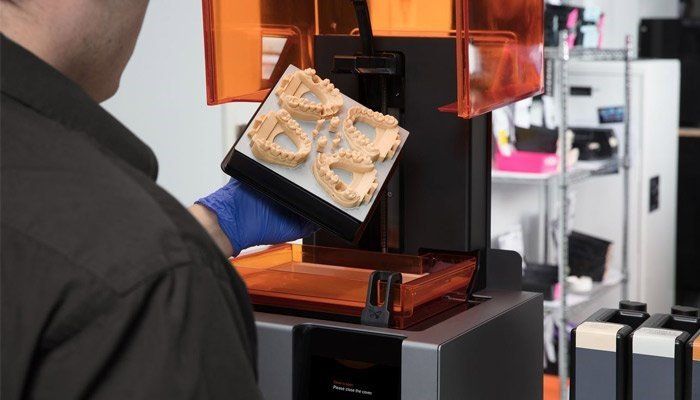

- Medical

- Military

- Maintenance

- Engineering and Manufacturing

The first 3D Printed Object in Space

- Industrialised AM isn’t hype, but adoption for mass production could take decades, not years

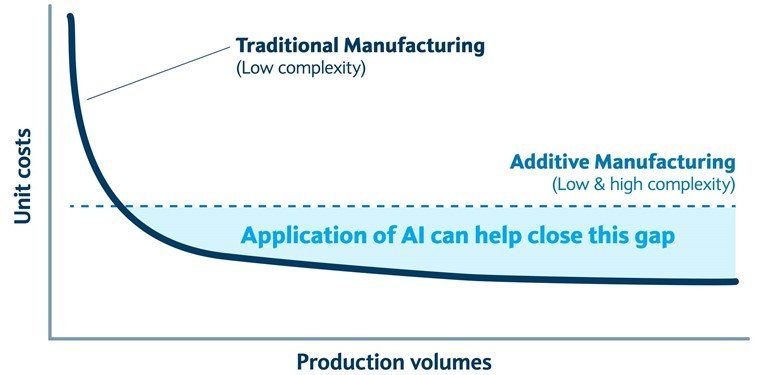

- The key to closing the economic advantage gap between Traditional and Additive Manufacturing

Our Services to Industry

We specialise in the Additive Manufacturing (3D Printing) of complex components, Product Development, Prototyping and Training.

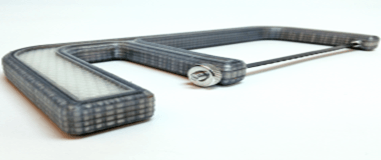

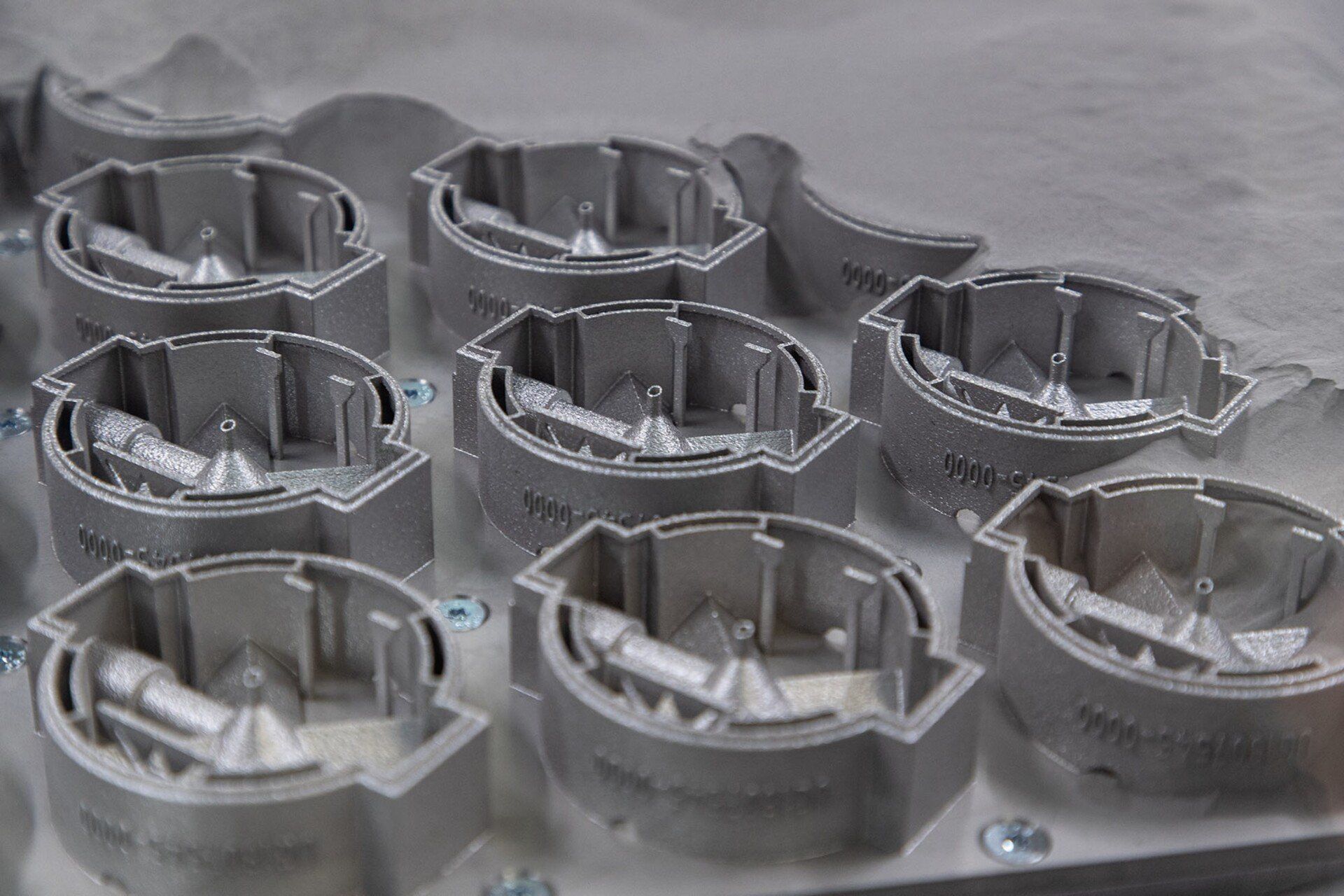

AM Design freedoms enable components to be designed and built to add value such as improved performance, light weighting, multi-part to single part, low volume production runs, prototyping, reverse engineering and supply chain value.

Our aim is to supply industrial Additive Manufactured components to our customers, helping them to fully utilise the technology to suit their individual needs and to solve their unique problems, working as a team, we deliver high quality products and service.

Benefits of the Additive process, such as: Part weight reduction, Multi-part to single component and Expanded design capabilities, allow our customers to re-think their approach to their designs in order to improve the efficiency, utility or aesthetics of their parts.

Supported by our experienced team, we are committed to supplying AM parts of the highest quality, and also sharing knowledge of the AM process to support potential users in their adoption of this technology.

Additive Manufacturing Capabilities;

- Designing to add value

- Dfam to optimise parts.

- Low volume production.

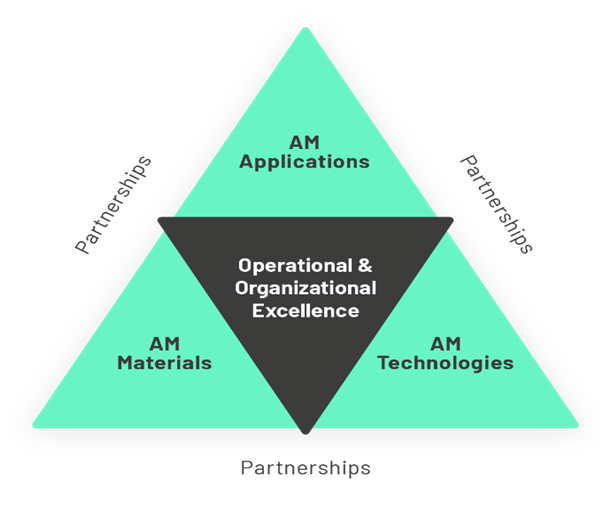

We encourage partnerships with our clients to explore Innovation Potential, AM Technologies, Materials and Applications

Examples of Successful Additive Manufacturing (3D Printing) applications for Customers